介质损耗因数测量仪 介质损耗(dielectric loss)指的是绝缘材料在电场作用下,由于介质电导和介质极化的滞后效应,在其内部引起的能量损耗。也叫介质损失,简称介损。

介质损耗因数(dielectric loss factor)指的是衡量介质损耗程度的参数。

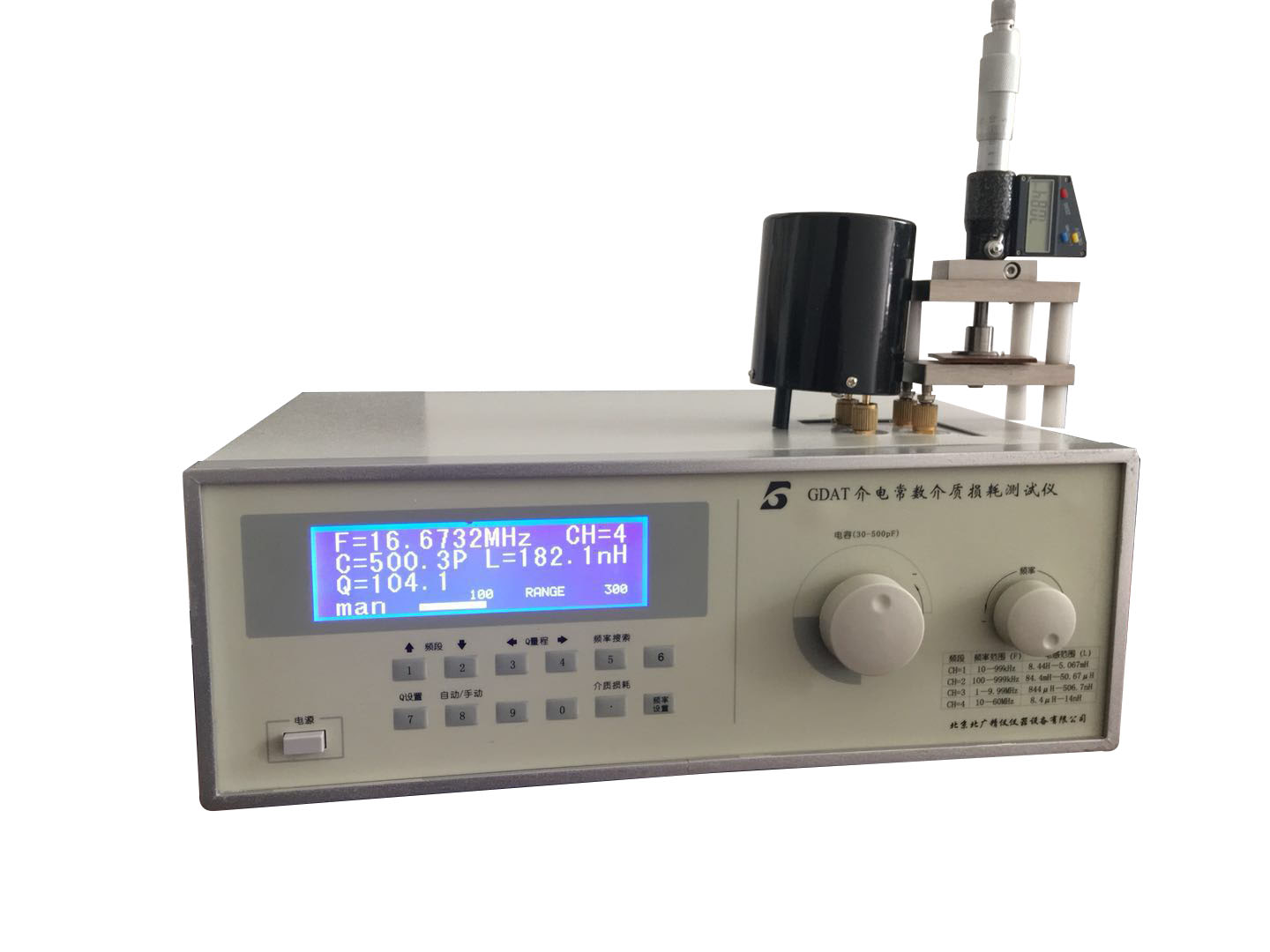

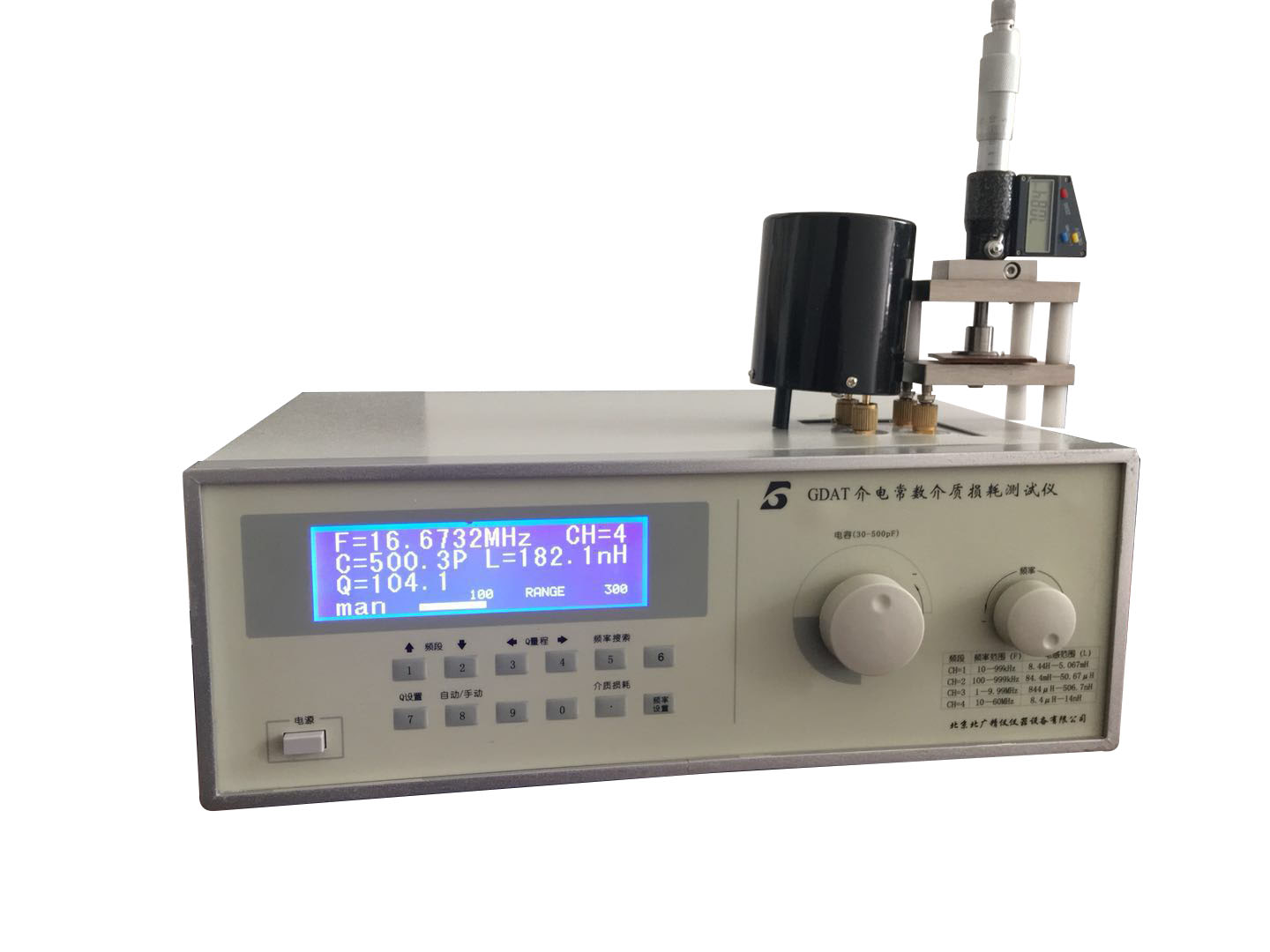

介质损耗因数测量仪 使用和保养

高频Q表是比较精密的阻抗测量仪器,在合理使用和注意保养情况下,才能保证长期稳定和较高的测试精度。

a.熟悉本说明书,正确地使用仪器;

b.使仪器经常保持清洁、干燥;

c.本仪器保用期为18个月,如发现机械故障或失去准确度,可以原封送回本厂,免费修理。

主要配置:

a.测试主机一台;

b.电感9只;

c.夹具一 套

测试注意事项

a.本仪器应水平安放;

b.如果你需要较精确地测量,请接通电源后,预热30分钟;

c.调节主调电容或主调电容数码开关时,当接近谐振点时请缓调;

d.被测件和测试电路接线柱间的接线应尽量短,足够粗,并应接触良好、可靠,以减少因接线的电阻和分布参数所带来的测量误差;

e.被测件不要直接搁在面板顶部,离顶部一公分以上,必要时可用低损耗的绝缘材料如聚苯乙烯等做成的衬垫物衬垫;

f.手不得靠近试件,以免人体感应影响造成测量误差,有屏蔽的试件,屏蔽罩应连接在低电位端的接线柱。

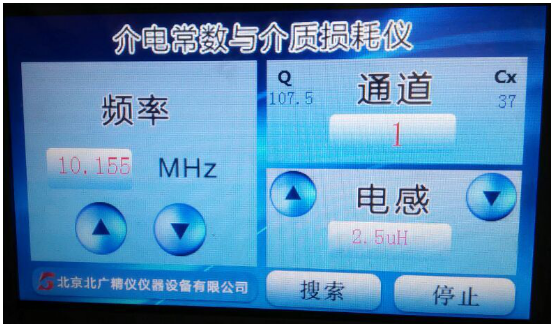

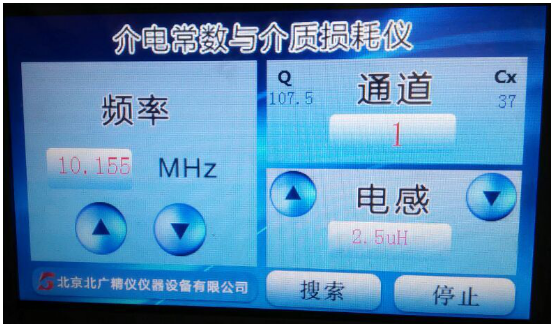

主要技术特性:

介质损耗和介电常数是各种电瓷、装置瓷、电容器等陶瓷,还有复合材料等的一项重要的物理性质,通过测定介质损耗角正切tanδ及介电常数(ε),可进一步了解影响介质损耗和介电常数的各种因素,为提高材料的性能提供依据;仪器的基本原理是采用高频谐振法,并提供了,通用、多用途、多量程的阻抗测试。它以单片计算机作为仪器的控制,测量核心采用了频率数字锁定,标准频率测试点自动设定,谐振点自动搜索,Q值量程自动转换,数值显示等新技术,改进了调谐回路,使得调谐测试回路的残余电感减至最低,并保留了原Q表中自动稳幅等技术,使得新仪器在使用时更为方便,测量值更为精确。仪器能在较高的测试频率条件下,测量高频电感或谐振回路的Q值,电感器的电感量和分布电容量,电容器的电容量和损耗角正切值,电工材料的高频介质损耗,高频回路有效并联及串联电阻,传输线的特性阻抗等。

为什么介电常数越大,绝缘能力越强?

因为物质的介电常数和频率相关,通常称为介电系数。

介电常数又叫介质常数,介电系数或电容率,它是表示绝缘能力特性的一个系数。所以理论上来说,介电常数越大,绝缘性能就越好。

注:这个性质不是绝对成立的。

对于绝缘性不太好的材料(就是说不击穿的情况下,也可以有一定的导电性)和绝缘性很好的材料比较,这个结论是成立的。

但对于两个绝缘体就不一定了。

介电常数反映的是材料中电子的局域(local)特性,导电性是电子的全局(global)特征.不是一回事情的。

补充:

电介质经常是绝缘体。其例子包括瓷器(陶器),云母,玻璃,塑料,和各种金属氧化物。有些液体和气体可以作为好的电介质材料。干空气是良好的电介质,并被用在可变电容器以及某些类型的传输线。蒸馏水如果保持没有杂质的话是好的电介质,其相对介电常数约为80。

对于时变电磁场,物质的介电常数和频率相关,通常称为介电系数。介电常数又叫介质常数,介电系数或电容率,它是表示绝缘能力特性的一个系数。

电极系统

1加到试样上的电极

电极可选用5.1.3中任意一种。如果不用保护环。而且试样上下的两个电极难以对齐时,其中一个电极应比另一个电极大些。已经加有电极的试样应放置在两个金属电极之间,这两个金属电极要比试样上的电极稍小些。对于平板形和圆柱形这两种不同电极结构的电容计算公式以及边缘电容近似计算的经验公式由表1给出.

对于介质损耗因数的测量,这种类型的电极在高频下不能满足要求,除非试样的表面和金属板都非常平整。图1所示的电极系统也要求试样厚度均匀

2试样上不加电极

表面电导率很低的试样可以不加电极而将试样插人电极系统中测量,在这个电极系统中,试样的一侧或两侧有一个充满空气或液体的间隙。

平板电极或圆柱形电极结构的电容计算公式由表3给出。

下面两种型式的电极装置特别合适

2.1空气填充测微计电极

当试样插人和不插人时,电容都能调节到同一个值,不需进行测量系统的电气校正就能测定电容率。电极系统中可包括保护电极.

2.2流体排出法

在电容率近似等于试样的电容率,而介质损耗因数可以忽略的一种液体内进行测量,这种测量与试样厚度测量的精度关系不大。当相继采用两种流体时,试样厚度和电极系统的尺寸可以从计算公式中消去

试样为与试验池电极直径相同的圆片,或对测微计电极来说,试样可以比电极小到足以使边缘效应忽略不计在测微计电极中,为了忽略边缘效应,试样直径约比测微计电极直径小两倍的试样厚度。

试验步骤

1试样的制备

试样应从固体材料上截取,为了满足要求,应按相关的标准方法的要求来制备。

应精确地测量厚度,使偏差在士(0. 2%士。.005 mm)以内,测量点应均匀地分布在试样表面。必要时,应测其有效面积。

2条件处理

条件处理应按相关规范规定进行。

3测量

电气测量按本标准或所使用的仪器(电桥)制造商推荐的标准及相应的方法进行。

在1 MHz或更高频率下,必须减小接线的电感对测量结果的影响。此时,可采用同轴接线系统(见图1所示),当用变电抗法测量时,应提供一个固定微调电容器。

测量方法的选择:

测量电容率和介质损耗因数的方法可分成两种:零点指示法和谐振法。

1零点指示法适用于频率不超过50 MHz时的测量。测量电容率和介质损耗因数可用替代法;也就是在接人试样和不接试样两种状态下,调节回路的一个臂使电桥平衡。通常回路采用西林电桥、变压器电桥(也就是互感藕合比例臂电桥)和并联T型网络。变压器电桥的优点:采用保护电极不需任何外加附件或过多操作,就可采用保护电极;它没有其他网络的缺点。

2谐振法适用于10 kHz一几百MHz的频率范围内的测量。该方法为替代法测量,常用的是变电抗法。但该方法不适合采用保护电极。

注:典型的电桥和电路示例见附录。附录中所举的例子自然是不全面的,叙述电桥和侧量方法报导见有关文献和该种仪器的原理说明书。

试验报告

试验报告中应给出下列相关内容:

绝缘材料的型号名称及种类、供货形式、取样方法、试样的形状及尺寸和取样日期(并注明试样厚度和试样在与电极接触的表面进行处理的情况);

试样条件处理的方法和处理时间;

电极装置类型,若有加在试样上的电极应注明其类型;

测量仪器;

试验时的温度和相对湿度以及试样的温度;

施加的电压;

施加的频率;

相对电容率ε(平均值);

介质损耗因数tans(平均值);

试验日期;

相对电容率和介质损耗因数值以及由它们计算得到的值如损耗指数和损耗角,必要时,应给出与温度和频率的关系。

特点:

◆ 优化的测试电路设计使残值更小

◆ 高频信号采用数码调谐器和频率锁定技术

◆LED数字读出品质因数,手动/自动量程切换

◆ 自动扫描被测件谐振点,标频单键设置和锁定,大大提高测试速度

电感:

线圈号 测试频率 Q值 分布电容p 电感值

9 100KHz 98 9.4 25mH

8 400KHz 138 11.4 4.87mH

7 400KHz 202 16 0.99mH

6 1MHz 196 13 252μH

5 2MHz 198 8.7 49.8μH

4 4.5MHz 231 7 10μH

3 12MHz 193 6.9 2.49μH

2 12MHz 229 6.4 0.508μH

1 25MHz,50MHz 233,211 0.9 0.125μH

Dielectric loss refers to the energy loss caused by the hysteresis effect of dielectric conductivity and polarization in insulating materials under the action of an electric field. Also known as dielectric loss, abbreviated as dielectric loss.

The dielectric loss factor refers to a parameter that measures the degree of dielectric loss.

Usage and maintenance

High frequency Q-meter is a relatively precise impedance measuring instrument, which can only ensure long-term stability and high testing accuracy under reasonable use and maintenance.

a. Familiarize yourself with this manual and use the instrument correctly;

b. Keep the instrument clean and dry regularly;

c. The warranty period of this instrument is 18 months. If mechanical failure or loss of accuracy is found, it can be returned to our factory in its original packaging for free repair.

Main configuration:

a. Test one host;

b. 9 inductors;

c. A set of fixtures

Testing precautions

a. This instrument should be placed horizontally;

b. If you need more accurate measurement, please preheat for 30 minutes after turning on the power;

c. When adjusting the main capacitor or digital switch of the main capacitor, please adjust slowly when approaching the resonance point;

d. The wiring between the tested component and the test circuit terminal should be as short and thick as possible, and should have good and reliable contact to reduce measurement errors caused by the resistance and distribution parameters of the wiring;

e. Do not place the test piece directly on the top of the panel, more than one centimeter away from the top. If necessary, use low loss insulation materials such as polystyrene to make padding;

f. Hands should not be close to the test piece to avoid measurement errors caused by human induction. For shielded test pieces, the shielding cover should be connected to the terminal at the low potential end.

Main technical features:

Dielectric loss and dielectric constant are important physical properties of various ceramics such as electrical ceramics, device ceramics, capacitors, and composite materials. By measuring the dielectric loss tangent tan δ and dielectric constant (ε), various factors affecting dielectric loss and dielectric constant can be further understood, providing a basis for improving material performance; The basic principle of the instrument is to use high-frequency resonance method and provide universal, multi-purpose, and multi range impedance testing. It uses a single-chip computer as the control of the instrument, and the measurement core adopts frequency digital locking, automatic setting of standard frequency test points, automatic search for resonance points, automatic conversion of Q value range, numerical display and other new technologies. It improves the tuning circuit, reduces the residual inductance of the tuning test circuit to the lowest, and retains the automatic amplitude stabilization technology in the original Q meter, making the new instrument more convenient to use and the measurement values more accurate. The instrument can measure the Q value of high-frequency inductors or resonant circuits, the inductance and distributed capacitance of inductors, the capacitance and loss tangent of capacitors, the high-frequency dielectric loss of electrical materials, the effective parallel and series resistance of high-frequency circuits, and the characteristic impedance of transmission lines under high testing frequency conditions.

Why does the larger the dielectric constant, the stronger the insulation ability?

Because the dielectric constant of a substance is frequency dependent, it is commonly referred to as the dielectric constant.

Dielectric constant, also known as dielectric constant, dielectric constant or permittivity, is a coefficient that represents the insulation capability characteristics. So theoretically, the larger the dielectric constant, the better the insulation performance.

Note: This property is not absolutely valid.

This conclusion holds true when comparing materials with poor insulation (meaning they can still have some conductivity without breakdown) to materials with good insulation.

But not necessarily for two insulators.

The dielectric constant reflects the local characteristics of electrons in a material, while conductivity is the global characteristic of electrons It's not just a one-time occurrence.

Addendum:

Dielectric materials are often insulators. Examples include porcelain (pottery), mica, glass, plastic, and various metal oxides. Some liquids and gases can serve as good dielectric materials. Dry air is a good dielectric and is used in variable capacitors and certain types of transmission lines. Distilled water is a good dielectric if it remains free of impurities, with a relative dielectric constant of about 80.

For time-varying electromagnetic fields, the dielectric constant of matter is frequency dependent and is commonly referred to as the dielectric constant. Dielectric constant, also known as dielectric constant, dielectric constant or permittivity, is a coefficient that represents the insulation capability characteristics.

Electrode system

1. Electrode added to the sample

The electrode can be selected from any of 5.1.3. If no protective ring is needed. And when the two electrodes on top and bottom of the sample are difficult to align, one electrode should be larger than the other. The sample with electrodes already added should be placed between two metal electrodes, which are slightly smaller than the electrodes on the sample. The capacitance calculation formulas for flat and cylindrical electrode structures, as well as the empirical formulas for approximate calculation of edge capacitance, are given in Table 1

For the measurement of dielectric loss factor, this type of electrode cannot meet the requirements at high frequencies unless the surface of the sample and the metal plate are very flat. The electrode system shown in Figure 1 also requires uniform sample thickness

Two samples without electrodes added

Samples with low surface conductivity can be measured by inserting them into an electrode system without adding electrodes. In this electrode system, there is a gap filled with air or liquid on one or both sides of the sample.

The capacitance calculation formula for flat or cylindrical electrode structures is given in Table 3.

The following two types of electrode devices are particularly suitable

2.1 Air filled micrometer electrode

When the sample is inserted or not, the capacitance can be adjusted to the same value without the need for electrical calibration of the measurement system to determine the capacitance rate. The electrode system may include protective electrodes

2.2 Fluid Discharge Method

Measuring in a liquid with a capacitance rate approximately equal to that of the sample and a negligible dielectric loss factor is not closely related to the accuracy of sample thickness measurement. When two fluids are used successively, the thickness of the sample and the size of the electrode system can be eliminated from the calculation formula

The sample is a circular disc with the same diameter as the electrode of the test cell, or for the micrometer electrode, the sample can be small enough to ignore edge effects in the micrometer electrode. In order to ignore edge effects, the sample diameter is approximately twice the thickness of the sample, which is smaller than the diameter of the micrometer electrode.

Experimental steps

Preparation of Sample 1

The sample should be taken from the solid material and prepared according to the relevant standard methods to meet the requirements.

The thickness should be measured accurately so that the deviation is within ? 0 2% of the population Within 0.05 mm, the measuring points should be evenly distributed on the surface of the specimen. If necessary, its effective area should be measured.

2 Condition Handling

Condition handling should be carried out in accordance with relevant regulations.

3 Measurements

Electrical measurements shall be conducted in accordance with this standard or the standards and corresponding methods recommended by the manufacturer of the instrument (bridge) used.

At frequencies of 1 MHz or higher, it is necessary to reduce the influence of the inductance of the wiring on the measurement results. At this point, a coaxial wiring system (as shown in Figure 1) can be used, and when measuring using the variable reactance method, a fixed fine-tuning capacitor should be provided.

Selection of measurement methods:

There are two methods for measuring capacitance and dielectric loss factor: zero point indication method and resonance method.

The zero point indication method is applicable for measurements with frequencies not exceeding 50 MHz. Alternative methods can be used to measure capacitance and dielectric loss factor; That is, adjust one arm of the circuit to balance the bridge in both the state of connecting and not connecting the sample. Usually, circuits use Xilin bridge, transformer bridge (i.e. mutual inductance coupled proportional arm bridge), and parallel T-shaped network. The advantages of transformer bridge: the use of protective electrodes does not require any additional accessories or excessive operation, and protective electrodes can be used; It does not have the drawbacks of other networks.

The resonance method is suitable for measurements in the frequency range of 10 kHz to several hundred MHz. This method is an alternative measurement method, commonly used is the variable reactance method. But this method is not suitable for using protective electrodes.

Note: Typical examples of bridges and circuits can be found in the appendix. The examples given in the appendix are naturally not comprehensive. The description of the bridge and measurement methods can be found in relevant literature and the principle manual of the instrument.

Test report

The following relevant content should be provided in the test report:

The model name and type of insulation material, supply form, sampling method, shape and size of the sample, and sampling date (with the thickness of the sample and the treatment of the sample on the surface in contact with the electrode indicated);

The method and processing time for sample condition treatment;

The type of electrode device, if there are electrodes added to the sample, their type should be indicated;

Measuring instrument;

The temperature and relative humidity during the experiment, as well as the temperature of the sample;

Applied voltage;

Applied frequency;

Relative permittivity ε (average value);

Dielectric loss factor tan (average value);

Test date;

The values of relative permittivity and dielectric loss factor, as well as the values calculated from them such as loss index and loss angle, should be given in relation to temperature and frequency if necessary.

characteristic:

Optimized test circuit design reduces residual value

High frequency signals use digital tuner and frequency locking technology

◆ LED digital readout quality factor, manual/automatic range switching

◆ Automatically scan the resonance point of the tested component, set and lock the standard frequency with a single key, greatly improving the testing speed

Inductance:

Coil number test frequency Q value distribution capacitance p inductance value

9 100KHz 98 9.4 25mH

8 400KHz 138 11.4 4.87mH

7 400KHz 202 16 0.99mH

6 1MHz 196 13 252μH

5 2MHz 198 8.7 49.8μH

4 4.5MHz 231 7 10μH

3 12MHz 193 6.9 2.49μH

2 12MHz 229 6.4 0.508μH

1 25MHz,50MHz 233,211 0.9 0.125μH