橡胶表面滑动摩擦磨损试验机 表面状态的影响

摩擦表面粗糙程度。润滑剂的存在,磨损碎片,橡胶表面老化和环境湿度都会大大改变橡胶的摩擦性能

1.表面状态不同时,摩擦的粘附成分变化明显,特别是有润滑剂时,粘附摩擦成分显著减少。

2.润滑和在橡胶制品表面涂有低摩擦系数的塑料,可以使摩擦系数减小,增大疲劳磨耗的成分,从而使磨耗减少。

橡胶表面滑动摩擦磨损试验机 试样要求

试样表面平整,无气泡、裂纹、分层、明显杂质和加工损伤等缺陷。每组试样不少于3个。

橡胶摩擦磨耗的影响因素

橡胶的磨耗主要有三种形式:

1.磨损磨耗:粗糙表面上凸出的尖锐粗糙物不断切割,刮擦

2.疲劳磨耗:硫化胶表面受周期性压缩,剪切,拉伸等形变作用

3.卷曲磨耗:光滑表面接触时硫化胶表面的微凹凸不平的地方发生变形。

主要配置及附件:(计算机控制)

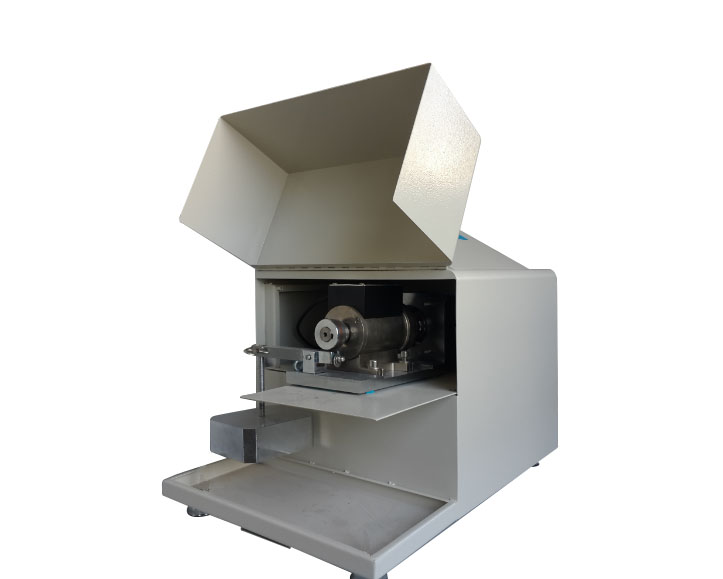

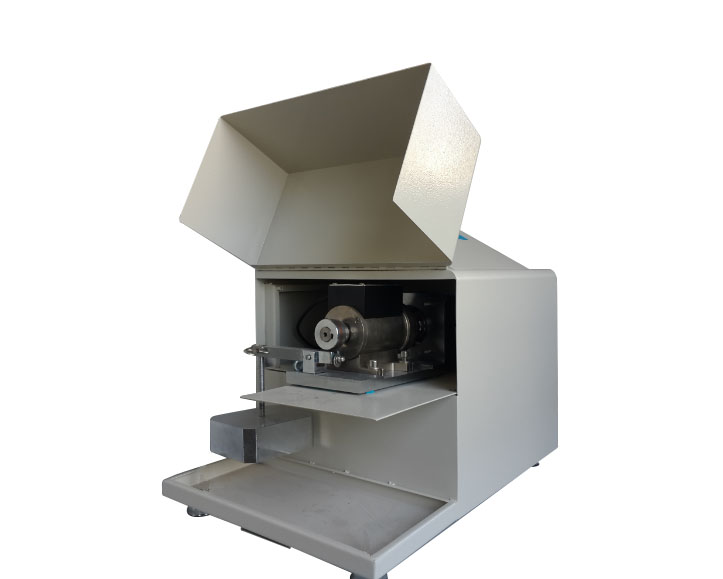

1、试验主机一台

2、高精度扭矩传感器一只

3、计算机数据采集卡一块

4、计算机一台(品牌)

5、彩色激光喷墨打印机一台

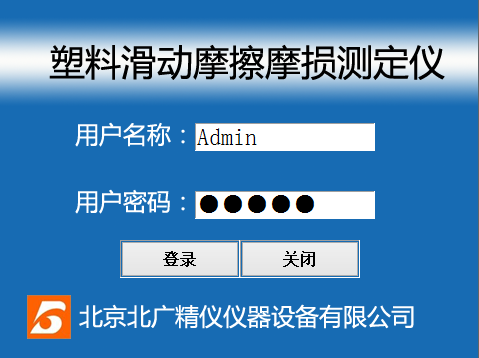

6、计算机控制软件一套

7、4Kg砝码两件(备用一套)

8、标准磨擦环四件(备用两件)

9、产品使用说明书一份

10、产品合格证

11、产品装箱单一份

12、整机重量:约87公斤

试验步骤

1、圆环应清除油污,贮存于干燥缸内以防生锈。

2、试样经状态调节后用感量为0.1毫克的分析天平称取其质量(M1)。

3、把试样装进夹具,摩擦面用角尺校正并使它与圆环的交线外于试样正中。装好摩擦力矩记录纸,开机校好零点。

4、再次用乙醇、丙酮等不与塑料起作用的溶剂仔细清除试样和圆环上的油污,此后不准再用手接触试样和圆环的表面。

5、平稳地加荷至选定的负荷值。

6、对磨2小时后停机卸负荷,取下试样和圆环,清理试样表面后,用精度不低于0.02毫米的量具测量磨痕宽度,或在试验环境下存放1小时后称取试样质量(m2)。

7、读取摩擦力矩值。

适用范围:

适用于塑料制品、橡胶制品、石墨板材或其他复合材料的滑动摩擦,磨损性能测试,也可对试验中试样的磨擦力、磨擦系数和磨损量进行测定。也可对试验中试样的磨擦力、磨擦系数和磨损量进行测定。

符合标准:

GB/T 3960-1983塑料滑动摩擦磨损试验方法GB/T 9141.8-1999柔性石墨板材滑动摩擦系数测试方法

摩擦磨损定义

1、摩擦:两物体接触表面间产生阻碍切向相对移动的现象称为摩擦。

2、滑动摩擦:两接触物体接触点具有不同速度时之摩擦。

3、摩擦力:两物体摩擦时相对移动的阻力。

4、摩擦系数:阻碍两物体相对运动的摩擦力对作用到物体表面的法向力之比。

5、磨损:物体相对运动时相互接触表面的物质不断损失或产生残余变形称为磨损。

技术参数:

1、试样尺寸:30mm?7mm?6mm;

2、转动速度: ≤200转/分(可调);

3、负荷:(20KG)196N?0.1%,可增至(40KG)392N;

4、摩擦环尺寸:≥¢40?10mm,倒角≥0.5?45?,外圆表面与内圆同心度偏差≤0.01;

5、摩擦环材质:45号钢;

6、摩擦力矩:0—4N.m;

7、砝码重量:4KG砝码十件,1KG砝码十件,可实现重量叠加功能;

8、精度:速度精度≤1%;负荷精度≤0.5%;摩擦力矩精度≤1%;计数器精度≤1S;传感器测量精度≤1%F。

状态调节

状态调节按GB2918-82《塑料试样状态调节和试验的标准环境》进行,温度为23?5摄氏度,温度为50?10%。

试验条件

试验中上转轴保持静止,下转轴以200转/分转动,摩擦副做滑动摩擦,对磨2小时,负荷20公斤,根据材料,允许选择其它负荷.试验环境温度为23?5摄氏度.

精度Precision:

1、速度精度:1%

2、负荷精度:0.5%

3、摩擦力矩精度:1%

4、计数器精度:1S

5、传感器测量精度:1% FS

功能特点:

1、试样尺寸:30mm?7mm?6mm

2、转动速度:0-500转/分 (可调)

3、负 荷:196N?0.1%(可增至392N)

4、摩擦环尺寸:¢40?10mm,倒角0.5?45?,外圆表面与内圆同心度偏差小于0.01

5、摩擦环材质:45号钢,淬火,热处理HRC40-45,外圆表面光洁度▼8

6、摩擦力矩:0--4N?m

7、砝码重量:4KG砝码一件,1KG砝码4件,可实现重量叠加功能。

适用范围及功能

符合标准:GB/T 3960-1983塑料滑动摩擦磨损试验方法GB/T 9141.8-1999柔性石墨板材滑动摩擦系数测试方法

另外本厂生产的计算机控制塑料滑动摩擦试验机是在现有电子塑料滑动摩擦试验机的基础上又增加了很多试验功能,可以同时显示扭矩-时间曲线,随意设定试验次数,显示当前试验次数,

设定时间及当前试验时间等多种功能,本机还配有彩色打印机,可以打印出带有曲线,表格数据,试验单位名头的精美的试验报告单。

The influence of surface condition

The roughness of the friction surface. The presence of lubricants, wear debris, aging of rubber surfaces, and environmental humidity can greatly alter the friction performance of rubber

1. When the surface condition is different, the adhesive components of friction change significantly, especially when there is lubricant, the adhesive friction components are significantly reduced.

Lubricating and coating the surface of rubber products with low friction coefficient plastic can reduce the friction coefficient, increase the composition of fatigue wear, and thus reduce wear.

Sample requirements

The surface of the sample is flat, without defects such as bubbles, cracks, delamination, obvious impurities, and processing damage. Each group of samples shall not be less than 3.

The influencing factors of rubber friction and wear

There are three main forms of rubber wear:

1. Wear and tear: Sharp and rough objects protruding from rough surfaces constantly cut and scrape

2. Fatigue wear: The surface of vulcanized rubber is subjected to cyclic compression, shear, tensile and other deformation effects

3. Curling wear: Deformation occurs in the slightly uneven areas on the surface of the vulcanized rubber when in contact with a smooth surface.

Main configuration and accessories: (computer control)

1. One test host

2. One high-precision torque sensor

3. One computer data acquisition card

4. One computer (brand)

5. One color laser inkjet printer

6. A set of computer control software

7. Two 4Kg weights (one spare set)

8. Four standard friction rings (two spare)

9. One copy of the product user manual

10. Product Qualification Certificate

11. Product packing list copy

12. Overall weight: approximately 87 kilograms

Test steps

1. The circular ring should be cleaned of oil stains and stored in a drying cylinder to prevent rusting.

2. After adjusting the state of the sample, weigh its mass (M1) using an analytical balance with a sensitivity of 0.1 milligrams.

3. Insert the sample into the fixture, calibrate the friction surface with an angle ruler, and ensure that its intersection with the circular ring is outside the center of the sample. Install the friction torque recording paper and turn on the machine to calibrate the zero point.

4. Carefully remove the oil stains on the sample and ring using solvents such as ethanol and acetone that do not interact with the plastic. Afterwards, do not touch the surface of the sample and ring with your hands.

5. Load steadily to the selected load value.

6. After grinding for 2 hours, stop the machine to unload the load, remove the sample and ring, clean the surface of the sample, measure the width of the grinding mark with a measuring tool with an accuracy of no less than 0.02 millimeters, or weigh the sample mass (m2) after storing in the test environment for 1 hour.

7. Read the friction torque value.

Applicable scope:

Suitable for sliding friction and wear performance testing of plastic products, rubber products, graphite sheets, or other composite materials. It can also measure the friction force, friction coefficient, and wear amount of the specimens in the test. It is also possible to measure the friction force, friction coefficient, and wear amount of the specimen in the experiment.

Compliant with standards:

GB/T 3960-1983 Test Method for Sliding Friction and Wear of Plastics GB/T 9141.8-1999 Test Method for Sliding Friction Coefficient of Flexible Graphite Sheet

Definition of Friction and Wear

1. Friction: The phenomenon of obstructing tangential relative movement between two objects in contact with each other is called friction.

2. Sliding friction: The friction between two objects in contact at different speeds.

3. Friction force: relative displacement between two objects when they rub against each other

售后服务

一、安装调试:协助试验机的安装,负责试验机的运输、调试。

二、验收标准:试验机按订货技术附件进行验收。终验收在买方进行,对用户提供的试样进行试验,并提供测试报告。

三、培训:安装调试同时,在仪器操作现场一次性免费培训操作人员2-3名,该操作人员应是由需方选派的长期稳定的员工,培训后能够对设备基本原理、软件使用、操作、维护事项理解和应用,使人员能够独立操作设备对样品进行检测、分析,同时能进行基本的维护。

四、软件升级:终生免费提供新版本控制软件。

业务咨询:932174181 媒体合作:2279387437 24小时服务热线:15136468001 盘古机械网 - 全面、科学的机械行业免费发布信息网站 Copyright 2017 PGJXO.COM 豫ICP备12019803号