在线离线一体TOC分析仪 二氧化碳传感器

仪器上安装有两个二氧化碳传感器,由电导率传感器和温度传感器组成。电导率测量采用双精度技术,可以实现自动校准和温度补偿。TIC传感器用于检测未经氧化的水样中二氧化碳浓度,同时检测水样的电导率值;TC传感器用于检测水样本身含有的二氧化碳和水样中有机物经分解后产生的二氧化碳浓度的总和。

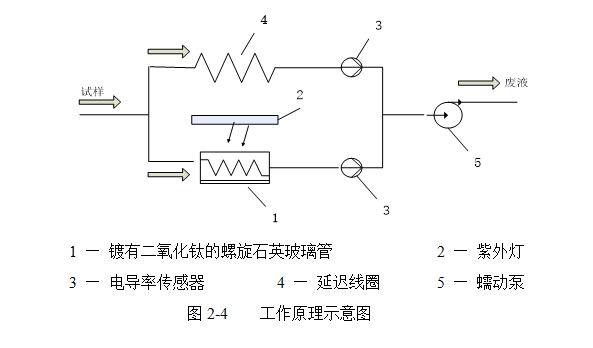

在线离线一体TOC分析仪 分流器

水样进入仪器后分成相同流量的两路,其中一路通过延迟线圈进入二氧化碳传感器,检测TIC,另一路通过氧化反应器利用紫外灯(UV灯)加二氧化钛薄膜光催化氧化作用将有机物分解为二氧化碳,进入二氧化碳传感器检测TC。总有机碳可通过这个差值计算得到:TOC = TC–TIC。

更换蠕动泵管

蠕动泵管在长期运行后会有磨损和老化现象,所以必须定期更换。

更换泵管的操作步骤如下:

○1 关闭主电源开关,拔去电源线。

○2 按下泵头下部的金属弹片,弹出两个塑料卡片。

○3 从甭管的接头处拆下旧的蠕动甭管,取下套在甭管上的抱箍,将抱箍套在新

的蠕动泵管上,然后将新的甭管装入仪器的接头上,要注意抱箍的位置及方向。

○4 将甭管嵌入两个塑料卡片,然后向下压入卡位。按下时一定要注意甭管是否

入槽。

○5 调整卡片上的流速调节键,要注意调整的原则是:管路出液口的液体顺畅自

然,无回流。条件允许的话,请使用高精度的量筒对出液速度进行测量,使液体的流

速与仪器的流速设置值相对应。

更换以上部件时存在问题可联系仪器厂家解决。

保存历史记录

历史记录的保存对象包括:在线分析结果和离线分析结果。

分析仪有两种存储模式,一种是自动存储;另一种是手动存储。当选择自动

存储时,每次测试结束后,仪器会自动保存本次的测试结果。当选择手动存储时,每

次开始测试的时候,仪器都会有提示信息,询问用户是否要保存数据。如果要保存测

试结果则按“确定”键保存,如果不保存,则按“取消”键放弃保存。

主要特征:

★高精度、高灵敏度,操作简单。

★人性化操作界面,有一键运行功能,自动管路清洗功能。

★高性能CPU,触摸屏设计,超大640*480点阵真彩显示器。

★不用拆开机箱更换UV灯和泵管。

★检测上限可设定,自动上限报警功能。

★具有RS232数据接口,历史数据可存储6个月。

★离线检测和在线检测可选配。

★具有打印功能

测定原理:仪器采用紫外氧化的原理,将水溶液中的总有机碳氧化为二氧化碳,并且测定其含量,二氧化碳的测试采用的是直接电导率法,通过测试经过氧化反应的水溶液总碳含量和未经过氧化反应的样品总无机碳的含量差值来测定总有机碳含量,即:总有机碳(TOC)=总碳(TC)-总无机碳(TIC)。

产品特点

1.仪器采用便携设计,使用轻便,方便移动至取样点。

2.采用嵌入式系统,触摸屏设计,纯中文操作方便简易。

3.针对制药用水(TOC含量在1000ppb以下)总有机碳含量的检测设计,进行检测。

4.配备大量的储存空间,能够存储大量的测试数据。

5.中文打印,输出测试参数、测试结果。

6.在使用、贮存和更换过程中不需要气体或试剂,无移动部件,减少维修和维护成本。

7.当测试样品浓度超过规定限度,仪器能够自动报警,并输出控制信号。

8.符合国家2010版《中国药典》规定的测试方案,可以提供IQ/OQ/PQ服务。

氧化反应器

仪器利用UV射线在二氧化钛光催化剂的作用下将有机化合物氧化成二氧化碳,氧化反应器是一个UV灯外包螺旋形的石英管。UV灯发出185nm和254nm的光线,使水产生光分解。

H2O hν(185nm)(TiO2)? OH? H?

羟基自由基(OH?)能完全把有机化合物氧化为二氧化碳。

有机物 OH?? CO2 H2O

UV灯的使用寿命为6个月,当更换时间到期时仪器将出现警告信息,提醒用户更换UV灯。

主要技术参数

电 源:220V?22V

检测极限:0.001mg/L

检测精度:?5%

检测范围:0.001mg/L~1.000mg/L

分析时间:4min

响应时间:15 min以内

样品温度:1-95℃

额定功率:100W

基本尺寸:44cm?18cm?26cm

相对湿度:≤ 85%

重复性误差:≤ 3%

环境温度:10-40℃ 温度变化在?5℃/d以内

内部样品流速:0.5 ml/min

零点漂移:?5%

量程漂移:?5%

电源频率:50Hz?1Hz

设备安装调试:

免费为用户提供所购仪器的安装调试服务。在进行安装调试前用户方应提供相应的准备工作,并予以提前通知,具体安装调试日期双方可以协商而定。设备安装调试由多年行业资深工程师免费进行。保证用户可以正确使用、软件操作和一般维护以及应及故障的处理。

Carbon dioxide sensor

There are two carbon dioxide sensors installed on the instrument, consisting of conductivity sensors and temperature sensors. The conductivity measurement adopts dual precision technology, which can achieve automatic calibration and temperature compensation. TIC sensors are used to detect the concentration of carbon dioxide in unoxidized water samples, while also detecting the conductivity value of the water samples; The TC sensor is used to detect the total concentration of carbon dioxide contained in the water sample itself and the carbon dioxide produced by the decomposition of organic matter in the water sample.

Diverter

After entering the instrument, the water sample is divided into two paths with the same flow rate. One path enters the carbon dioxide sensor through a delay coil to detect TIC, while the other path decomposes organic matter into carbon dioxide through the photocatalytic oxidation of titanium dioxide film using a UV lamp in an oxidation reactor, and enters the carbon dioxide sensor to detect TC. The total organic carbon can be calculated by this difference: TOC=TC–TIC.

Replace the peristaltic pump tube

The peristaltic pump tube may experience wear and aging after long-term operation, so it must be replaced regularly.

The operation steps for replacing the pump tube are as follows:

Turn off the main power switch and unplug the power cord.

Press the metal spring at the bottom of the pump head and pop out two plastic cards.

○3 Remove the old peristaltic pipe from the joint of the pipe, remove the clamp on the pipe, and place the clamp on the new one

On the peristaltic pump tube, then install the new tube into the joint of the instrument, paying attention to the position and direction of the clamp.

Insert two plastic cards and then press them down into the slots. Be sure to pay attention when pressing, regardless of whether it is pressed or not

Enter the slot.

Adjust the flow rate adjustment key on the card, and pay attention to the principle of adjustment: the liquid at the outlet of the pipeline should be smooth and self regulating

However, there is no reflux. If conditions permit, please use a high-precision measuring cylinder to measure the liquid flow rate and ensure the flow of the liquid

The speed corresponds to the flow rate setting of the instrument.

If there are any problems when replacing the above components, please contact the instrument manufacturer for resolution.

Save History

The objects for saving historical records include online analysis results and offline analysis results.

The analyzer has two storage modes, one is automatic storage; Another method is manual storage. When selecting automatic

When storing, the instrument will automatically save the test results after each test is completed. When selecting manual storage, every

At the beginning of the next test, the instrument will display a prompt message asking the user if they want to save the data. If you want to save the test

Press the "OK" button to save the test results. If you do not want to save, press the "Cancel" button to discard the save.

Main features:

★High precision, high sensitivity, and simple operation.

★Humanized operation interface, with one click operation function and automatic pipeline cleaning function.

★High performance CPU, touch screen design, large 640 * 480 dot matrix true color display.

★No need to open the chassis to replace the UV lamp and pump tube.

★The detection upper limit can be set, with automatic upper limit alarm function.

★Equipped with RS232 data interface, historical data can be stored for 6 months.

★Offline detection and online detection are optional.

★With printing function

Measurement principle: The instrument adopts the principle of ultraviolet oxidation to oxidize the total organic carbon in the aqueous solution to carbon dioxide and determine its content. The carbon dioxide test uses the direct conductivity method, which determines the total organic carbon content by measuring the difference between the total carbon content of the oxidized aqueous solution and the total inorganic carbon content of the unoxidized sample. That is, total organic carbon (TOC)=total carbon (TC) - total inorganic carbon (TIC).

Product features

1. The instrument adopts a portable design, which is lightweight and easy to move to the sampling point.

2. Adopting embedded system and touch screen design, pure Chinese operation is convenient and simple.

3. Design and conduct testing for the total organic carbon content of pharmaceutical water (TOC content below 1000ppb).

4. Equipped with a large amount of storage space, capable of storing a large amount of test data.

5. Print in Chinese, output test parameters and test results.

6. No gas or reagents are required during use, storage, and replacement, and there are no moving parts, reducing repair and maintenance costs.

When the concentration of the test sample exceeds the specified limit, the instrument can automatically alarm and output a control signal.

8. According to the testing plan specified in the 2010 edition of the Chinese Pharmacopoeia, IQ/OQ/PQ services can be provided.

Oxidation reactor

The instrument uses UV rays to oxidize organic compounds into carbon dioxide under the action of titanium dioxide photocatalyst. The oxidation reactor is a spiral shaped quartz tube wrapped around a UV lamp. UV lamps emit light at 185nm and 254nm, causing aquatic products to undergo photodegradation.

H2O hν(185nm) (TiO2) OH? H?

Hydroxyl radicals (OH?) can completely oxidize organic compounds into carbon dioxide.

Organic matter OH?CO2 H2O

The service life of UV lamps is 6 months. When the replacement time expires, the instrument will display a warning message to remind users to replace the UV lamp.

Main technical parameters

Power supply: 220V?22V

Detection limit: 0.001mg/L

Detection accuracy:?5%

Detection range: 0.001mg/L~1.000mg/L

Analysis time: 4 minutes

Response time: Within 15 minutes

Sample temperature: 1-95℃

Rated power: 100W

Basic size: 44cm?18cm?26cm

Relative humidity:≤85%

Repeatability error:≤3%

Environmental temperature: 10-40℃Temperature variation within?5℃/d

Internal sample flow rate: 0.5 ml/min

Zero drift:?5%

Range drift:?5%

Power frequency: 50Hz?1Hz

Equipment installation and debugging:

Provide users with free installation and debugging services for the purchased instruments. Before installation and debugging, the user should provide corresponding preparation work and give advance notice. The specific installation and debugging date can be negotiated by both parties. The equipment installation and debugging are carried out free of charge by experienced engineers in the industry for many years. Ensure that users can use the software correctly, perform software operations and general maintenance, and handle malfunctions promptly.

业务咨询:932174181 媒体合作:2279387437 24小时服务热线:15136468001 盘古机械网 - 全面、科学的机械行业免费发布信息网站 Copyright 2017 PGJXO.COM 豫ICP备12019803号