离线纯水TOC分析仪 总有机碳分析仪是北京北广精仪公司自主研发的高精度总有机碳分析仪器。产品使用电导率差值检测技术,检测精度高,响应时间短。产品符合国家法规和标准,可满足制药用水、注射用水、超纯水和去离子水的在线及离线的检测要求。

离线纯水TOC分析仪 参数:

1 | 测量范围 | 0.01mg/L~1.000 mg/L |

2 | 精度 | ?4% |

3 | 分辨率 | 0.001mg /L |

4 | 分析时间 | 40分钟 |

5 | 响应时间 | 8分钟 |

6 | 检测极限 | 0.001mg /L |

7 | 样品温度 | 1- 95℃ |

8 | 电源要求/功能 | 220V |

9 | 重复性误差 | ≤3% |

10 | 显示屏 | 彩色触摸屏 |

测试工序的流程

TOC 分析仪的测试工作方式为自动化进行。测试人员需要做好测试前的准备工

作,在具体测试过程中不需要调整和值守。

TOC 分析仪的测试项目包括:

1) 在线分析 ;

2) 离线分析 ;

3) 系统适应性验证;

4) 零点校准 。

仪器校准

‘仪器校准’主要包括两部分内容,一是仪器的零点校准;

二是药典里规定的仪器必须满足的系统适应性试验。这两项测试功能的进样方式都采用手动确认的模式。该部分还设有一个管路冲洗的功能,用于管路的快速清洗,此功能大大缩短了管路清洗的时间。

使用与操作方法

开始检测并计入检测次数,检测完毕后显示最后一次检测结果,其中几次检测的结果均自动保存在查询记录当中。检测次数的设置方式为:用“选择”键移动光标,用“设置”键修改数字,按“确定”键进行确认,进入分析界面。先进行四次冲洗过程

易耗品更换周期

UV灯和蠕动泵管可以从本公司购买。UV灯为185nm、254nm双波长紫外灯,蠕动泵管为进口泵管,具有高品质和良好的稳定性。易耗品更换周期参考表5.1。

表5.1 易耗品维护/更换表

部件名称 | 更换周期* |

UV灯 | 12个月 |

蠕动泵管 | 12个月 |

二氧化碳传感器

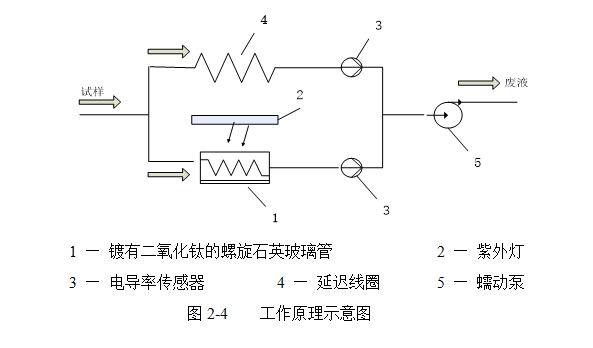

仪器上安装有两个二氧化碳传感器,由电导率传感器和温度传感器组成。电导率测量采用双精度技术,可以实现自动校准和温度补偿。TIC传感器用于检测未经氧化的水样中二氧化碳浓度,同时检测水样的电导率值;TC传感器用于检测水样本身含有的二氧化碳和水样中有机物经分解后产生的二氧化碳浓度的总和。

主要特征:

1、高精度、高灵敏度,操作简单。

2、人性化操作界面,有一键运行功能,自动管路清洗功能。

3、高性能CPU,触摸屏设计,超大640*480点阵真彩显示器。

4、不用拆开机箱更换UV灯和泵管。

5、检测上限可设定,自动上限报警功能。

6、具有RS232数据接口,历史数据可存储6个月。

7、离线检测和在线检测可选配。

8、具有打印功能

离线检测

离线检测时,仪器可从样品瓶或其它没有压力的容器直接取样。仪器管路冲洗和仪器校准应在离线状态操作。若样品中有不可溶性微粒,应经过滤膜(孔径60μm或更小)过滤后进入仪器,以防止样品中的微粒阻塞仪器。仪器的进样管为1/16英寸的Teflon管,经蠕动泵抽进管路中的水样流速约为0.5 ml/min。

零点校准

仪器校准的目的是为了减小传感器的零点漂移,并对其测试曲线进行修订,对于保证仪器测试结果的准确性有非常重要的意义。

校准周期可以根据具体使用情况而定,建议更换紫外灯或仪器使用半年以后校准一次。出现数据分析的结果偏差较大时,也可进行校验。

仪器在校准过程过程中,将用到两种标准液,一种是总有机碳低于0.1ppm,电导率低于 1.0μs/cm(25℃)的高纯水作为零点水;另一种是 0.5ppm 的标准蔗糖溶液。

a) 零点水和标准溶液要采用密闭容器内盛放,容器的顶空要尽量小,密封口打开后要尽快测试。

b) 配制校准溶液之前,蔗糖标准品必须在 105℃(221?F)环境下干燥至恒重。

低浓度高纯水在空气中暴露超过一小时,会因溶解了空气中的二氧化碳而使电导率值明显增大。

二氧化碳测量循环

仪器每4分钟检测得出一个数据(包括TOC值和电导率值),在4分钟的测量循环中TC和TIC是独立检测的。

更换UV 灯

更换UV 灯时,须小心操作,以免损坏灯管及其周围的螺旋状石英管。

给客户提供新UV 灯管时,附送一双手套供安装时使用,避免在 UV 灯管表面和螺

旋状石英管表面留下指纹。指纹会吸收UV 光线、降低氧化反应器的氧化性能。同时

在安装新的UV 灯管之前可以使用乙醇去除指纹和污垢,保证 UV 灯表面的透光率。

更换UV 灯具体操作:

○1 关闭主电源开关,拔去电源线。

○2 将仪器机箱后盖板的螺钉拧开,打开后盖板。

○3 拔掉连接灯管的电源线插头,并柠松灯管座的锁紧螺母,慢慢抽出灯管。

○4 换上新灯管并调整灯管在螺旋石英管中的有效位置,拧紧锁紧螺母。

○5 插好灯管的电源线插头并将机箱后盖板螺丝拧紧,更换结束。

更换以上部件时存在问题可联系仪器厂家解决。

The total organic carbon analyzer is a high-precision total organic carbon analysis instrument independently developed by Beijing Beiguang Jingyi Company. The product uses conductivity difference detection technology, with high detection accuracy and short response time. The product complies with national regulations and standards, and can meet the online and offline testing requirements for pharmaceutical water, injection water, ultrapure water, and deionized water.

Parameters:

1. Measurement range: 0.01mg/L to 1.000 mg/L

2 Precision?4%

3 Resolution 0.001mg/L

4 Analysis time of 40 minutes

5 response times of 8 minutes

6 detection limit of 0.001mg/L

Sample temperature 1-95℃

8 Power Requirements/Function 220V

9. Repeatability error≤3%

10 display color touch screen

The process of testing process

The testing method of TOC analyzer is automated. Testers need to prepare well before testing

During the specific testing process, there is no need to adjust or be on duty.

The testing items for TOC analyzer include:

1) Online analysis;

2) Offline analysis;

3) System adaptability verification;

4) Zero point calibration.

Instrument calibration

Instrument calibration mainly includes two parts: first, zero point calibration of the instrument;

The second is the system adaptability test that the instruments specified in the pharmacopoeia must meet. The injection method for both testing functions adopts manual confirmation mode. This section also has a pipeline flushing function for quick cleaning of pipelines, which greatly shortens the cleaning time of pipelines.

Usage and operation methods

Start the detection and count the number of detections. After the detection is completed, the last detection result will be displayed, and the results of several detections will be automatically saved in the query record. The way to set the number of detections is to use the "Select" key to move the cursor, use the "Set" key to modify the number, press the "OK" key to confirm, and enter the analysis interface. Perform four flushing processes first

Replacement cycle of consumables

UV lamps and peristaltic pump tubes can be purchased from our company. The UV lamp is a dual wavelength UV lamp with 185nm and 254nm wavelengths, and the peristaltic pump tube is an imported pump tube, which has high quality and good stability. Refer to Table 5.1 for the replacement cycle of consumables.

Table 5.1 Maintenance/Replacement of Consumables

Component Name Replacement Cycle*

UV lamp for 12 months

Peristaltic pump tube for 12 months

Carbon dioxide sensor

There are two carbon dioxide sensors installed on the instrument, consisting of conductivity sensors and temperature sensors. The conductivity measurement adopts dual precision technology, which can achieve automatic calibration and temperature compensation. TIC sensors are used to detect the concentration of carbon dioxide in unoxidized water samples, while also detecting the conductivity value of the water samples; The TC sensor is used to detect the total concentration of carbon dioxide contained in the water sample itself and the carbon dioxide produced by the decomposition of organic matter in the water sample.

Main features:

1. High precision, high sensitivity, and simple operation.

2. Humanized operation interface, with one click operation function and automatic pipeline cleaning function.

3. High performance CPU, touch screen design, large 640 * 480 dot matrix true color display.

4. No need to open the chassis to replace the UV lamp and pump tube.

5. The detection upper limit can be set, with automatic upper limit alarm function.

6. Equipped with RS232 data interface, historical data can be stored for 6 months.

7. Offline detection and online detection are optional.

8. With printing function

Offline detection

When conducting offline testing, the instrument can directly take samples from sample bottles or other containers without pressure. Instrument pipeline flushing and instrument calibration should be operated offline. If there are insoluble particles in the sample, they should be filtered through a membrane with a pore size of 60μAfter filtering (m or smaller), enter the instrument to prevent particles in the sample from blocking the instrument. The sampling tube of the instrument is a 1/16 inch Teflon tube, and the water sample flow rate pumped into the pipeline through a peristaltic pump is about 0.5 ml/min.

Zero calibration

The purpose of instrument calibration is to reduce the zero drift of sensors and revise their test curves, which is of great significance in ensuring the accuracy of instrument test results.

The calibration cycle can be determined based on specific usage conditions. It is recommended to replace the UV lamp or calibrate the instrument after six months of use. When there is a significant deviation in the results of data analysis, verification can also be carried out.

During the calibration process of the instrument, two standard solutions will be used: one with a total organic carbon content below 0.1ppm and a conductivity below 1.0μUsing high-purity water at s/cm (25℃) as zero point water; Another type is a standard sucrose solution of 0.5ppm.

a) Zero point water and standard solution should be stored in a closed container, with the top space of the container as small as possible. After the sealing port is opened, testing should be carried out as soon as possible.

b) Before preparing the calibration solution, the sucrose standard must be dried to a constant weight at 105℃(221?F).

Low concentration high-purity water exposed to air for more than an hour will significantly increase its conductivity due to the dissolution of carbon dioxide in the air.

Carbon dioxide measurement cycle

The instrument detects data every 4 minutes (including TOC and conductivity values), and TC and TIC are independently detected during the 4-minute measurement cycle.

Replace UV lamp

When replacing a UV lamp, be careful to avoid damaging the lamp tube and its surrounding spiral quartz tubes.

When providing new UV tubes to customers, a pair of gloves are included for installation to avoid contact with the surface and screws of the UV tubes

Fingerprints are left on the surface of the spiral quartz tube. Fingerprints absorb UV light and reduce the oxidation performance of the oxidation reactor. At the same time

Before installing a new UV lamp, ethanol can be used to remove fingerprints and dirt, ensuring the transparency of the UV lamp surface.

Specific steps for replacing UV lamps:

Turn off the main power switch and unplug the power cord.

Unscrew the screws on the back cover of the instrument case and open the back cover.

Pull out the power cord plug connecting the lamp tube and loosen the locking nut of the lamp tube holder, slowly pulling out the lamp tube.

Replace the lamp with a new one and adjust the effective position of the lamp in the spiral quartz tube, tighten the locking nut.

Insert the power cord plug of the lamp tube and tighten the screws on the back cover of the chassis, and the replacement is complete.

If there are any problems when replacing the above components, please contact the instrument manufacturer for resolution.

业务咨询:932174181 媒体合作:2279387437 24小时服务热线:15136468001 盘古机械网 - 全面、科学的机械行业免费发布信息网站 Copyright 2017 PGJXO.COM 豫ICP备12019803号