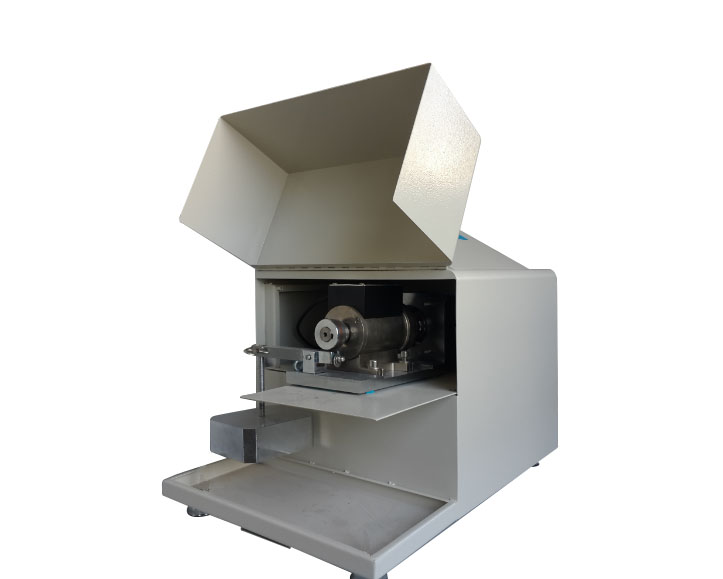

塑料滑动摩擦磨损试验机 功能:

本厂生产的计算机控制塑料滑动摩擦试验机是在现有电子塑料滑动摩擦试验机的基础上又增加了很多试验功能,可以同时显示扭矩-时间曲线,随意设定试验次数,显示当前试验次数,设定时间及当前试验时间等多种功能,本机还配有彩色打印机,可以打印出带有曲线,表格数据,试验单位名头的精美的试验报告单。

塑料滑动摩擦磨损试验机 特点:

1、系统运行稳定,可靠性高。

2、结构紧凑,使用方便,简单。

3、采用高精度电机、驱动机、传感器,精度高。

4、具有试验人员分级管理功能。

5、实时显示摩擦系数-时间,扭矩-时间曲线。

6、试验报告可打印试验参数,试验数据,曲线,备注等信息,简单,方便,可编辑。

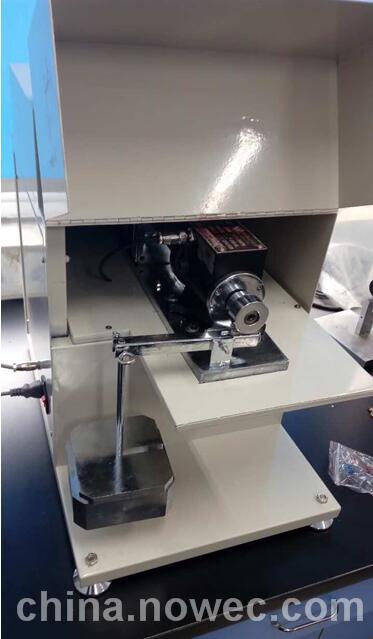

7、试样尺寸: 30mm?7mm?6mm

8、转动速度: 0-500转/分 (可调)

9、负 荷: 196N ? 0.1%(可增至392N)

10、摩擦环尺寸:¢40?10mm ,倒角0.5?45?,外圆表面与内圆同心度偏差小于0.01

11、摩擦环材质:45号钢,淬火,热处理HRC40-45,外圆表面光洁度▼8

12、摩擦力矩: 0--4N?m

13、砝码重量:4KG砝码一件,1KG砝码4件,可实现重量叠加功能。

技术参数:

1、速度精度:1%

2、负荷精度:0.5%

3、摩擦力矩精度:1%

4、计数器精度:1S

5、传感器测量精度:1% FS

符合标准:

GB/T 3960-1983 塑料滑动摩擦磨损试验方法 GB/T 9141.8-1999 柔性石墨板材滑动摩擦系数测试方法

主要配置及附件:(计算机控制)

1、试验主机一台

2、高精度扭矩传感器一只

3、计算机数据采集卡一块

4、计算机一台(品牌)

5、彩色激光喷墨打印机一台

6、计算机控制软件一套

7、4Kg 砝码两件(备用一套)

8、标准磨擦环四件(备用两件)

9、产品使用说明书一份

10、产品合格证

11、产品装箱单一份

12、整机重量:约87 公斤

硬件安装及连线

1、将电源线插入设备后边的电源插口。

2、将控制和采集线一端接到设备控制端口,另一端接到计算机上。

3、正确连接电脑接线

试样要求

试样表面平整,无气泡、裂纹、分层、明显杂质和加工损伤等缺陷。每组试样不少于3个。

试验条件

试验中上转轴保持静止,下转轴以200转/分转动,摩擦副做滑动摩擦,对磨2小时,负荷20公斤,根据材料,允许选择其它负荷.试验环境温度为23?5摄氏度.

试验报告

试验报告应包括下列内容:

A.塑料名称、规格、牌号、生产厂;

B.试样的制备方法,摩擦表面状况,测定的试样个数;

C.环境温度、温度及状态调节条件;

D.圆环材质、硬度、光洁度和外径尺寸;

E.试验负荷;

F.试验结果:磨痕宽度或体积磨损及摩擦系数的测定结果;

G.试验日期、人员。

试验步骤

1、圆环应清除油污,贮存于干燥缸内以防生锈。

2、试样经状态调节后用感量为0.1毫克的分析天平称取其质量(M1)。

3、把试样装进夹具,摩擦面用角尺校正并使它与圆环的交线外于试样正中。装好摩擦力矩记录纸,开机校好零点。

4、再次用乙醇、丙酮等不与塑料起作用的溶剂仔细清除试样和圆环上的油污,此后不准再用手接触试样和圆环的表面。

5、平稳地加荷至选定的负荷值。

6、对磨2小时后停机卸负荷,取下试样和圆环,清理试样表面后,用精度不低于0.02毫米的量具测量磨痕宽度,或在试验环境下存放1小时后称取试样质量(m2)。

7、读取摩擦力矩值。

状态调节

状态调节按GB2918-82《塑料试样状态调节和试验的标准环境》进行,温度为23?5摄氏度,温度为50?10%。

Function:

The computer-controlled plastic sliding friction testing machine produced by our factory has added many testing functions on the basis of the existing electronic plastic sliding friction testing machine. It can simultaneously display the torque time curve, freely set the number of tests, display the current number of tests, set the time and the current test time, and other functions. The machine is also equipped with a color printer, which can print exquisite test reports with curves, table data, and test unit names.

characteristic:

1. The system runs stably and has high reliability.

2. Compact structure, easy to use, and simple.

3. Adopting high-precision motors, drivers, and sensors, with high precision.

4. It has the function of grading and managing experimental personnel.

5. Real time display of friction coefficient time and torque time curves.

6. The test report can print test parameters, test data, curves, notes, and other information, which is simple, convenient, and editable.

7. Sample size: 30mm?7mm?6mm

8. Rotation speed: 0-500 revolutions per minute (adjustable)

9. Load: 196N ? 0.1% (can be increased to 392N)

10. Friction ring size:¢40 ? 10mm, chamfer 0.5 ? 45 ?, concentricity deviation between outer and inner surfaces less than 0.01

11. Friction ring material: 45 steel, quenched, heat treated HRC40-45, outer surface smoothness ▼ 8

12. Friction torque: 0--4N?m

13. Weight of weights: One 4KG weight and four 1KG weights, which can achieve weight stacking function.

Technical parameters:

1. Speed accuracy: 1%

2. Load accuracy: 0.5%

3. Friction torque accuracy: 1%

4. Counter accuracy: 1S

5. Sensor measurement accuracy: 1% FS

Compliant with standards:

GB/T 3960-1983 Plastic Sliding Friction and Wear Test Method GB/T 9141.8-1999 Flexible Graphite Sheet Sliding Friction Coefficient Test Method

Main configuration and accessories: (computer-controlled)

1. One experimental host

2. One high-precision torque sensor

3. One computer data acquisition card

4. One computer (brand)

5. One color laser inkjet printer

6. A set of computer control software

7. Two 4Kg weights (one set for backup)

8. Four standard friction rings (two spare)

9. One copy of the product user manual

10. Product Qualification Certificate

11. Product packing list copy

12. Whole machine weight: approximately 87 kilograms

Hardware installation and wiring

1. Insert the power cord into the power socket at the back of the device.

2. Connect one end of the control and acquisition cable to the device control port and the other end to the computer.

3. Connect the computer wiring correctly

Sample requirements

The surface of the sample is flat, without defects such as bubbles, cracks, delamination, obvious impurities, and processing damage. Each group shall have no less than 3 samples.

Experimental conditions

In the experiment, the upper shaft remains stationary and the lower shaft rotates at 200 revolutions per minute. The friction pair performs sliding friction and grinds for 2 hours with a load of 20 kilograms. Depending on the material, other loads can be selected The experimental environment temperature is 23 ? 5 degrees Celsius

Test report

The test report should include the following contents:

A. Plastic name, specification, brand, and manufacturer;

B. The preparation method of the sample, the condition of the friction surface, and the number of samples measured;

C. Environmental temperature, temperature and state regulation conditions;

D. Circular ring material, hardness, smoothness, and outer diameter size;

E. Test load;

F. Test results: Measurement results of abrasion width or volume wear and friction coefficient;

G. Test date and personnel.

Experimental steps

1. The circular ring should be cleaned of oil stains and stored in a drying cylinder to prevent rusting.

2. After adjusting the state of the sample, weigh its mass (M1) using an analytical balance with a sensitivity of 0.1 milligrams.

3. Insert the sample into the fixture, calibrate the friction surface with an angle ruler, and ensure that its intersection with the circular ring is outside the center of the sample. Install the friction torque recording paper and start the machine to calibrate the zero point.

4. Carefully remove the oil stains on the sample and the ring using solvents such as ethanol and acetone that do not work with plastic. After that, do not touch the surface of the sample and ring with your hands.

5. Smoothly load to the selected load value.

6. After grinding for 2 hours, stop the machine to unload the load, remove the sample and ring, clean the surface of the sample, measure the width of the grinding mark with a measuring tool with an accuracy of not less than 0.02 millimeters, or weigh the sample mass (m2) after storing it in the test environment for 1 hour.

7. Read the torque value of friction force.

State adjustment

The state adjustment shall be carried out in accordance with GB2918-82 "Standard Environment for State Adjustment and Testing of Plastic Specimens", with a temperature of 23 ? 5 degrees Celsius and a temperature of 50 ? 10%.

我厂主要产品有:拉力材料试验机,海绵泡沫落球回弹试验机,海绵泡沫压陷硬度测验仪,海绵泡沫疲劳压陷试验机,熔融指数仪,塑料滑动摩擦磨损试验机,电压击穿试验仪,塑料球压痕硬度计,马丁耐热试验仪,海绵泡沫拉伸强度试验机,介电常数与介质损耗测试仪,电容率测试仪,体积表面积电阻率测试仪,低温脆性冲击试验仪,维卡热变形试验仪,哑铃制样机,阿克隆磨耗试验机,简支梁冲击试验机,悬臂梁冲击试验机,熔体流动速率仪,无转子硫化仪等。

想了解其它相关信息,欢迎登录北京北广精仪仪器设备有限公司网站或电询我们相关人员。

关于仪器质保:1、北广仪器保证提供的设备为需方指定的全新设备,其各项技术指标均符合相关的产品技术要求。2、设备经客户验收合格后,开始计算保修期,设备免费保修期为壹年,设备在质量保质期内,产品在非人为损坏的情况下,由北广仪器负责全保。北广仪器的客服在得到通知后24小时内响应,安排约定维修细节。3、质保期后,我们免费为您维修维护设备,除大型设备外所有设备一律返厂维修,经检验后,电话告知客户问题所在及解决方式,经客户同意后进行维修,维修后发回客户,对于损坏及更换的零部件我们只收取成本费;如客户不认同我们的检验结果,双方另协商维修细节。

业务咨询:932174181 媒体合作:2279387437 24小时服务热线:15136468001 盘古机械网 - 全面、科学的机械行业免费发布信息网站 Copyright 2017 PGJXO.COM 豫ICP备12019803号